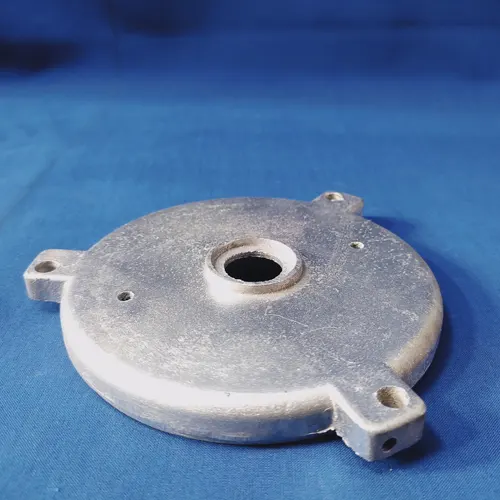

Gravity Die Casting

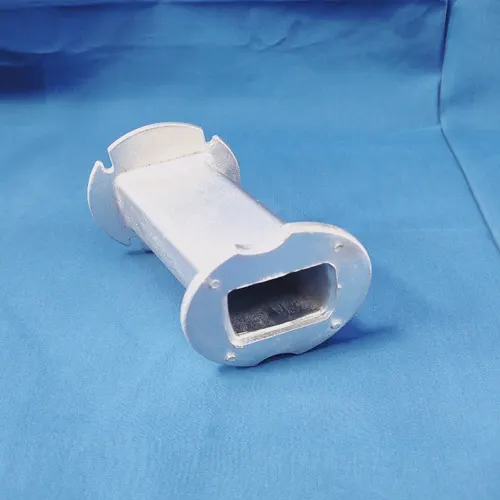

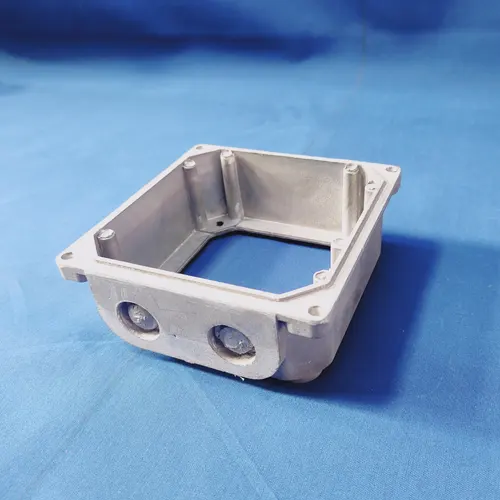

Gravity Die Casting (GDC) is a permanent mold casting process where molten aluminium is poured into a preheated metal die using gravity, without external pressure. This process ensures high-quality, dimensionally accurate castings with excellent surface finish and mechanical properties. GDC is widely used for producing complex and durable components for industries such as automotive, aerospace, marine and machine tools. It is ideal for medium to high-volume production and allows for efficient material utilization and minimal defects.

Pressure Die Casting

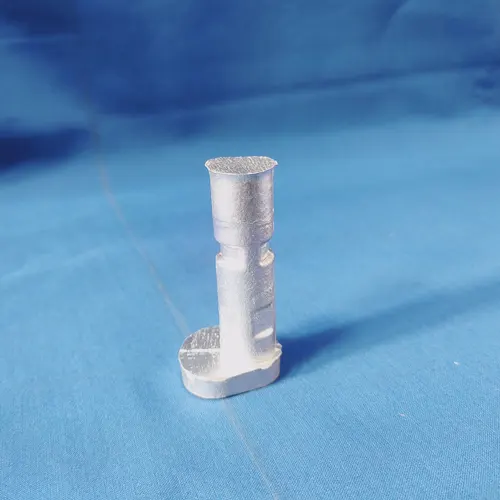

Weight Range : 10gms to 1.5kg

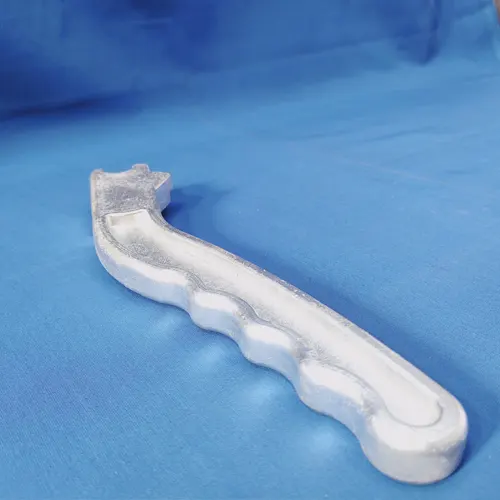

Pressure Die Casting Rotors(PDC) is a high-precision casting process where molten aluminium is injected into a steel mold under high pressure. This method produces intricate, lightweight, and strong components with excellent surface finish and dimensional accuracy. PDC is widely used in the automotive, aerospace, electronics, industrial sectors for manufacturing parts like engine components, housings and structural elements. The process ensures high production efficiency, minimal material waste and consistent quality making it ideal for mass production.

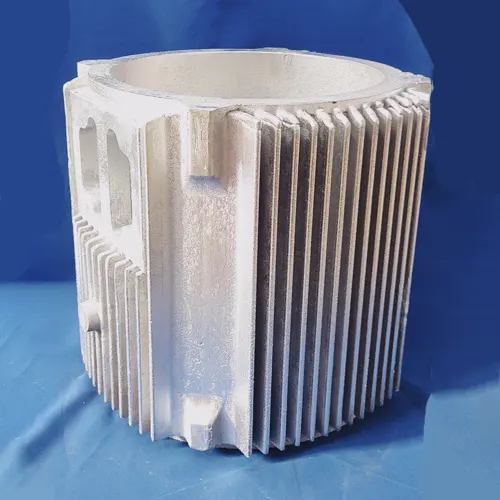

Pressure Die Casting Rotors

Pressure Die Casting Rotors(PDC) is a high-precision manufacturing process where molten aluminium is injected into a steel mold under high pressure to create durable and lightweight components. Pressure Die Casting Rotors benefit from this technique, ensuring superior dimensional accuracy, excellent surface finish and enhanced mechanical strength. These rotors are widely used in the automotive, industrial, electrical sectors, providing efficient performance, reduced material waste and high production efficiency.